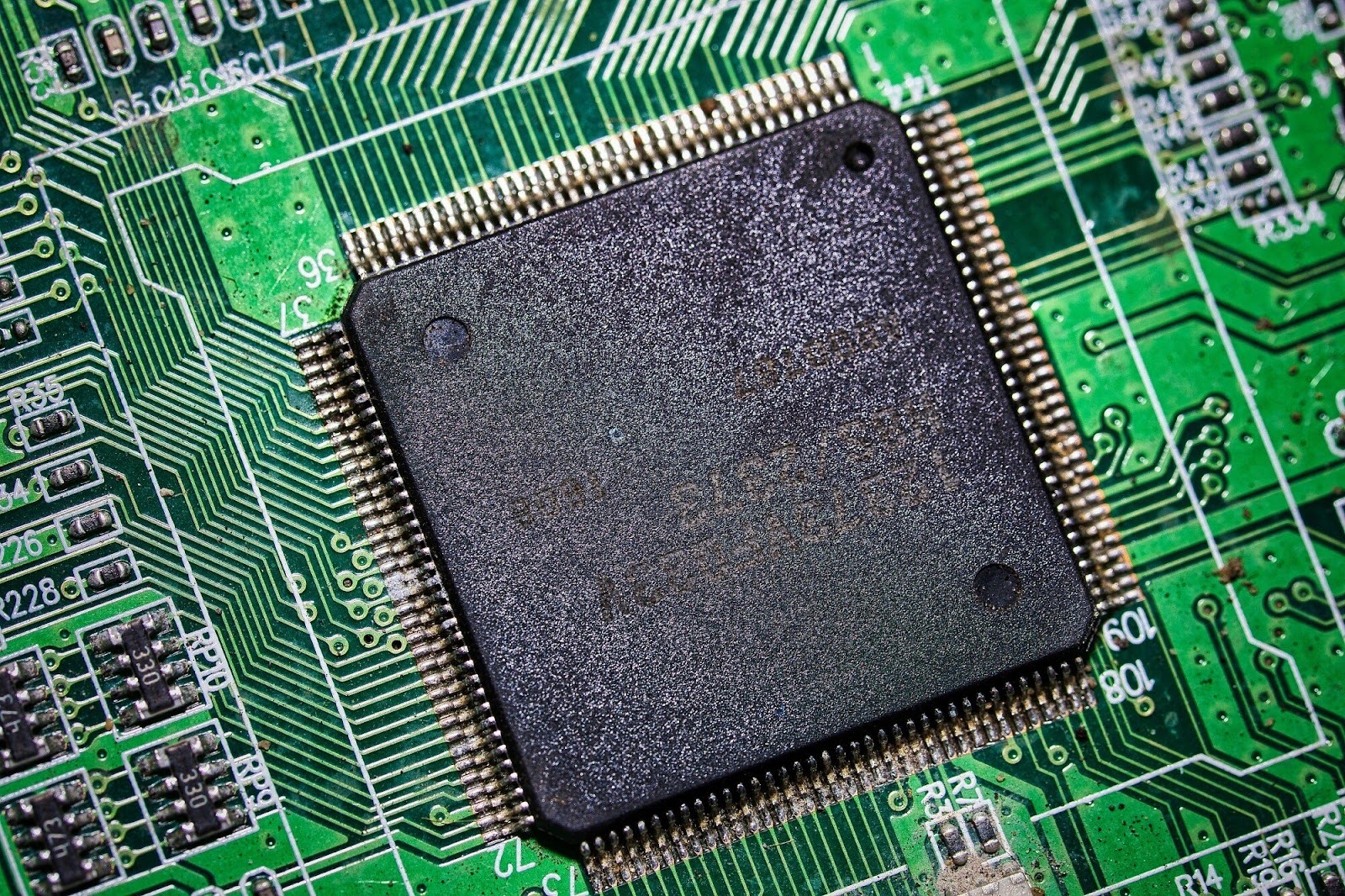

When it comes to selecting an electronic enclosure, several critical factors come into play. These enclosures, used to house electronic equipment, play a vital role in protecting components from environmental hazards and ensuring their optimal function. This guide aims to assist you in navigating the various considerations involved in choosing the right electronic enclosure, from material selection and design features to compliance with industry standards.

Material Selection

In the realm of electronic enclosures, the material constitutes a foundational decision. Several options exist, each with its unique advantages and potential downsides. Metal enclosures, for instance, are renowned for their robustness and heat dissipation properties, making them suitable for high-power electronics. On the other hand, plastic enclosures offer better insulation and come in a variety of aesthetically pleasing designs, ideal for consumer electronics.

However, choosing a material isn’t solely about weighing the advantages. It’s crucial to consider the potential drawbacks as well. For instance, while metals provide strength and durability, they can be prone to corrosion if not properly treated. Meanwhile, although plastic enclosures are relatively inexpensive and versatile, they may not withstand extreme temperatures or harsh environmental conditions as effectively as their metal counterparts.

Lastly, it’s worth considering specialty materials. For example, stainless steel or fiberglass enclosures might be a wise choice for applications in harsh environments, such as industrial or marine settings. Similarly, EMI/RFI shielded enclosures may be necessary for applications with sensitive electronics that could be adversely affected by electromagnetic or radio frequency interference. The folks at www.budind.com note that consulting with an experienced enclosure manufacturer can help you determine the best material for your specific application. It’s always better to be safe than sorry.

Design Features

The design of an electronic enclosure can significantly impact its performance and usability. First, consider the necessary internal layout. How components are arranged within the enclosure can affect heat buildup, ease of maintenance, and even signal integrity. Therefore, the layout needs to be carefully planned to optimize the performance of the electronic device.

Furthermore, the design should consider ease of access for installation, maintenance, and repair. For instance, removable panels or doors can make it easier to install and maintain the internal components. Also, the enclosure’s design could allow for the addition of mounting brackets for secure placement or a handle for mobility, depending on the application.

Compliance with Industry Standards

Compliance with industry standards is an essential factor to consider when choosing an electronic enclosure. Depending on the application, various standards may apply, such as IP ratings for ingress protection or UL ratings for safety. Ensuring your enclosure meets the necessary standards can help protect your electronics and ensure they operate reliably.

Also, standards compliance can have significant implications for the marketability of your product. For example, products that meet specific industry standards may be easier to sell in certain markets or to certain customer groups. Therefore, understanding and meeting these standards can provide a competitive advantage.

Moreover, non-compliance with relevant standards can result in significant penalties, including fines and product recalls. It’s essential to stay updated on the latest changes to relevant standards and ensure your products remain compliant. To this end, working with a knowledgeable and reputable enclosure manufacturer can be invaluable.

Environmental Considerations

The environmental conditions where the enclosure will be used should heavily influence your decision. If the enclosure will be used outdoors or in harsh environments, it needs to be robust and able to withstand factors such as moisture, dust, and temperature fluctuations.

Thermal management is another crucial consideration, especially for high-power electronics. If components generate a lot of heat, the enclosure must be designed with adequate ventilation or even integrated cooling systems to prevent overheating and ensure reliable operation.

Finally, regard the potential for physical impacts or vibrations. If the enclosure will be used in an environment where these are common, such as in industrial machinery or transportation applications, you’ll need an enclosure designed to be rugged and resistant to shock and vibration.

Cost Considerations

While quality and performance are vital, cost is a factor that invariably comes into play when choosing an electronic enclosure. Metal enclosures, while durable and often higher performing, are usually more expensive than plastic alternatives. However, the long-term reliability and performance advantages they offer can justify the higher upfront cost.

Beyond the material, other cost factors come into play. For instance, custom-designed enclosures are generally more expensive than off-the-shelf solutions, but they offer the advantage of being perfectly suited to your specific application. Additionally, the cost of any necessary surface treatment to prevent corrosion or enhance electrical insulation should be taken into account.

Lastly, it’s crucial to consider the total cost of ownership. This includes the initial cost of the enclosure, as well as long-term costs such as maintenance, potential replacement, and even energy costs if the enclosure includes built-in cooling systems. By taking a holistic view of costs, you can make a more informed decision that balances quality, performance, and affordability.

In conclusion, choosing the right electronic enclosure involves weighing various factors, from material selection and design features to compliance with industry standards and environmental considerations. By carefully considering each of these elements, you can ensure your electronics are adequately protected and perform optimally in their intended application. Remember to consult with experts and reputable manufacturers to guide you in making the best decision for your specific needs.