Auto engineering plays a critical role in optimizing the efficiency and performance of vehicles, striving to strike a balance between fuel economy and power. With the increasing importance of environmental sustainability and rising fuel costs, auto engineers have focused on developing innovative technologies and design principles that maximize fuel efficiency while delivering optimal power output.

This article explores how auto engineering achieves efficiency and performance enhancements, highlighting key areas such as engine design, aerodynamics, hybridization, and advanced materials.

Engine design: Unleashing power with efficiency

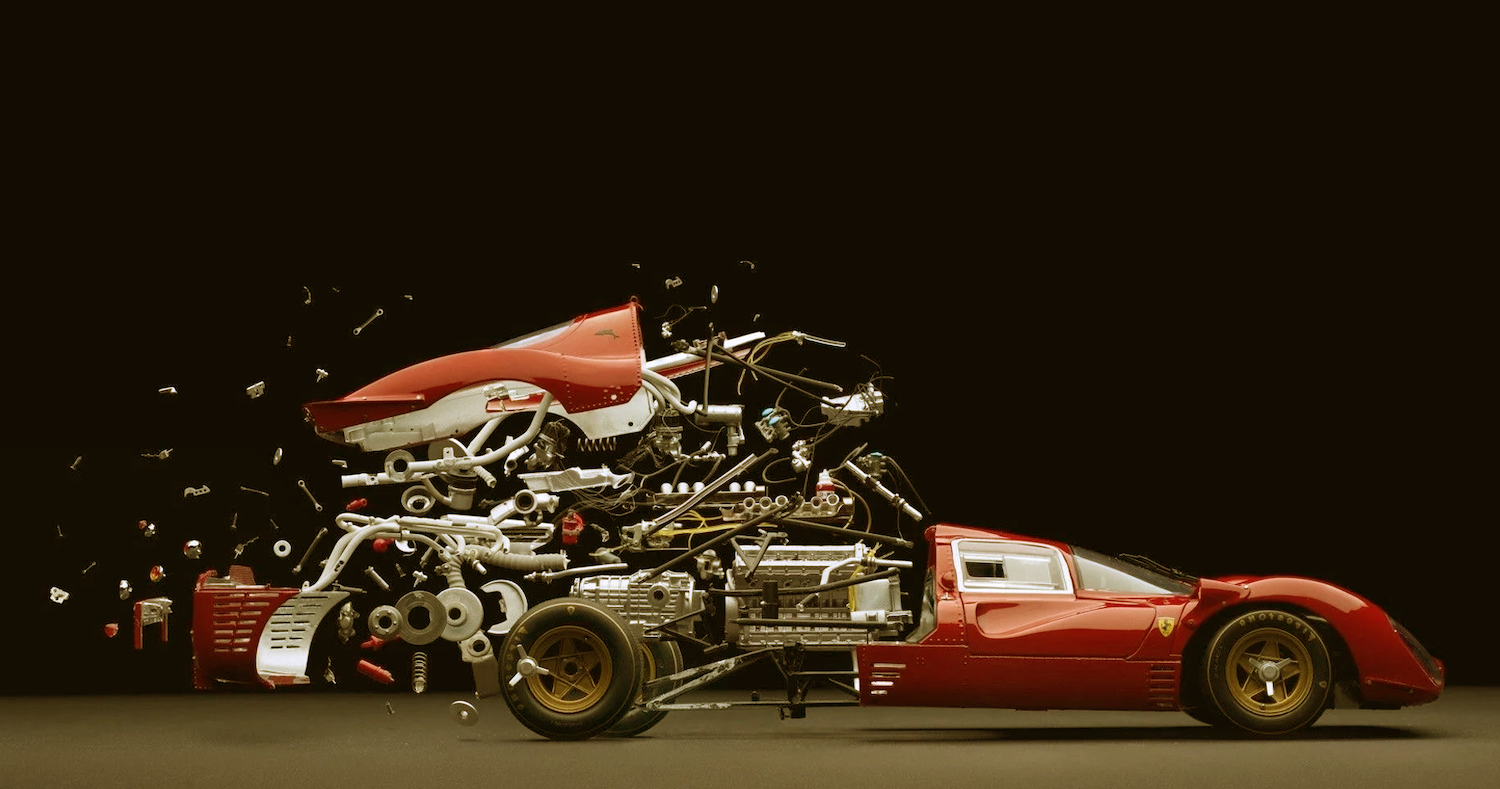

Engine design is at the forefront of optimizing fuel economy and power output. Auto engineers employ various strategies to enhance the efficiency of internal combustion engines while ensuring they deliver the desired performance. One critical aspect is improving the combustion process itself. Advancements such as direct fuel injection, variable valve timing, and turbocharging have revolutionized engine efficiency.

Direct fuel injection allows for more precise fuel delivery, improving combustion and reducing fuel consumption. Variable valve timing optimizes the opening and closing of engine valves, enabling better control over airflow and enhancing efficiency across different engine speeds and loads. Turbocharging utilizes exhaust gasses to drive a turbine that forces more air into the engine, resulting in increased power output without sacrificing fuel efficiency.

Auto engineers also explore engine downsizing, which involves replacing larger-displacement engines with smaller ones that maintain power output through turbocharging or supercharging. This approach reduces internal friction and weight, improving fuel efficiency without compromising performance. Engine start-stop systems are another notable feature that automatically shut off the engine when the vehicle comes to a stop, conserving fuel during idle times and contributing to improved fuel economy.

Aerodynamics: Cutting through the air with ease

Aerodynamics plays a significant role in optimizing both fuel economy and performance. Auto engineers meticulously design vehicles to reduce drag and improve airflow, enabling vehicles to cut through the air with minimal resistance. Streamlined body shapes, sculpted contours, and optimized underbody panels are some techniques employed to enhance aerodynamic efficiency.

By reducing drag, vehicles experience less resistance, which translates to improved fuel efficiency. The decreased aerodynamic drag contributes to better high-speed stability and reduced wind noise. To achieve these benefits, auto engineers employ wind tunnel testing, computational fluid dynamics (CFD), and advanced simulation tools to analyze and refine vehicle designs, ensuring they minimize air resistance while meeting aesthetic and functional requirements.

In addition to the vehicle’s overall shape, auto engineers pay attention to specific aerodynamic features such as active grille shutters, air curtains, and rear spoilers. Active grille shutters adjust airflow through the front grille to optimize engine cooling and reduce drag. Air curtains create a controlled pathway for air around the front wheels, reducing turbulence and improving aerodynamic efficiency. Rear spoilers are designed to manage airflow over the vehicle, reducing turbulence at higher speeds and improving stability.

Hybridization: Combining power sources for efficiency

Hybridization has emerged as a practical approach to optimizing fuel economy and performance by combining power sources. Hybrid vehicles typically incorporate an internal combustion engine and an electric motor, allowing for seamless integration and management of power delivery. Auto engineers optimize the operation of hybrid systems to maximize fuel efficiency and enhance performance.

In a hybrid system, the electric motor provides additional power during acceleration, reducing the load on the internal combustion engine and improving overall fuel economy. Regenerative braking is another critical feature in hybrid vehicles where the electric motor acts as a generator, converting kinetic energy during braking into electrical energy that is stored in the battery. This energy can then power the vehicle during low-speed or stop-and-go driving, reducing reliance on the internal combustion engine.

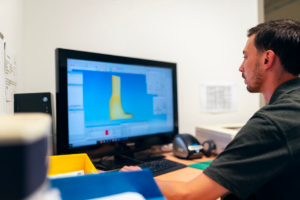

OBD2 scanners: Standardized diagnostics for all vehicles

One of the most notable advancements in diagnostic technology is the introduction of On-Board Diagnostics 2 (OBD2) scanners. OBD2 is a standardized diagnostic system mandated by regulations in many countries, including the United States and Europe. It requires vehicles to have a standardized diagnostic connector, allowing universal access to diagnostic information across different makes and models.

OBD2 scanners provide a standardized method of retrieving diagnostic trouble codes and accessing real-time data from a vehicle’s onboard computer systems when technicians check OBD2 codes. They offer compatibility with all OBD2 compliant vehicles, ensuring technicians can diagnose and troubleshoot a wide range of vehicles using a single scanner. This standardized approach simplifies the diagnostic process, eliminates the need for multiple proprietary scanning tools, and reduces diagnostic costs for technicians and vehicle owners.

OBD2 scanners support various diagnostic functionalities beyond retrieving DTCs. They can read and display live sensor data, monitor the status of various vehicle systems, and perform specialized tests and functions. OBD2 scanners often provide access to generic diagnostic information and code definitions, enabling technicians to effectively interpret and understand the diagnostic trouble codes.

All things considered

Efficiency and performance are critical considerations in auto engineering, and technological advancements continue to drive innovations in achieving the optimal balance between fuel economy and power output. Engine design, aerodynamics, hybridization, and advanced materials are essential areas where auto engineers focus their efforts.

By continually pushing the boundaries of innovation, auto engineering plays a vital role in shaping a future where vehicles offer enhanced efficiency and exhilarating performance. The ongoing pursuit of efficiency and performance benefits drivers and contributes to a greener and more sustainable transportation ecosystem.